Quality

We take quality very seriously at Constance Machine. The only thing worse than making a bad part is for it to go out to a customer, so we keep a wide variety of precision measuring tools on hand to make sure every part meets the print. We check parts both at the machine and in our QC room to make sure that we are getting consistent, accurate results every time. We use only top quality tooling from the likes of Zeiss, Mitutoyo, and Starrett so you know we are getting results you can trust. We have extensive GD&T knowledge, and we can provide reports on all part dimensions if requested. We guarantee all designs we handle will remain confidential, and we are able to work under an NDA if requested. All part quality inspection is done in the USA out of our Everett, Washington facility. If you want to work with a company with a proven track record for quality, please contact Constance Machine today for a free quote!

inspection Process

- First Article Inspection (FAI): Before full production begins, the first part off the machine is thoroughly inspected to verify compliance with all customer and engineering specifications.

- In-Process Inspection: Operators perform routine checks during machining using calibrated precision tools such as micrometers, calipers, height gauges, and bore gauges to maintain consistency.

- Final Inspection: Each component undergoes a comprehensive final inspection by a dedicated quality control technician using CMMs (Coordinate Measuring Machines), optical comparators, and surface roughness testers when applicable.

Documentation & Continuous Improvement

- All measuring instruments are calibrated regularly and traceable to NIST standards.

- Inspection reports, material certifications, and process documentation are maintained and provided upon request to ensure full traceability and accountability.

- Our team is committed to continuous improvement through regular audits, customer feedback analysis, and employee training.

- Root cause analysis and corrective action procedures are in place to address non-conformances quickly and effectively.

Considerations

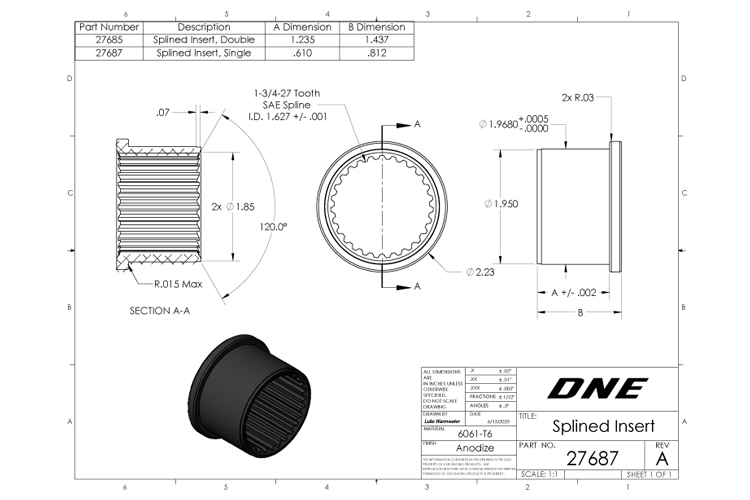

- A well thought out drawing is the key to getting great parts.

- Consider marking critical dimensions, and try to exclude unimportant dimensions that we can get from the model.

- Use clear, concise notes to avoid any ambiguity.

- Extremely tight tolerances will likely increase the price of the part, so try to use them only when necessary.